Highly flexible, stretchable, transparent and electrically conductive electrodes are used to create foldable displays for smartphones and smartwatches. However, the flexibility of current transparent devices, made of metal oxides of zinc and indium, is limited.

Theoretical results show that metal nanowire films exhibit performances that rival those of metal oxides, but, in practice, how can we fabricate such flexible, transparent electrodes?

A team of researchers from Telangana and Tamil Nadu recently succeeded in doing just that. They developed a transparent electrode from ultrathin gold and platinum films using a tri-layer architecture: gold-platinum-gold. To create the tri-layer, the researchers adopted a method that is useful to make thin films at relatively high purity and moderate cost: magnetron sputtering. In magnetron sputtering, metal atoms are ejected from metals in high vacuum conditions. Guided by a magnetic field, the metals are deposited as ultra-thin layers on a flexible substrate. The researchers used polyethylene terephthalate as the substrate.

The tri-layer film was only 6 nanometres thick. Conventional metal oxide films are almost 8 times thicker and, therefore, heavier. Yet there was no compromise on electrical properties.

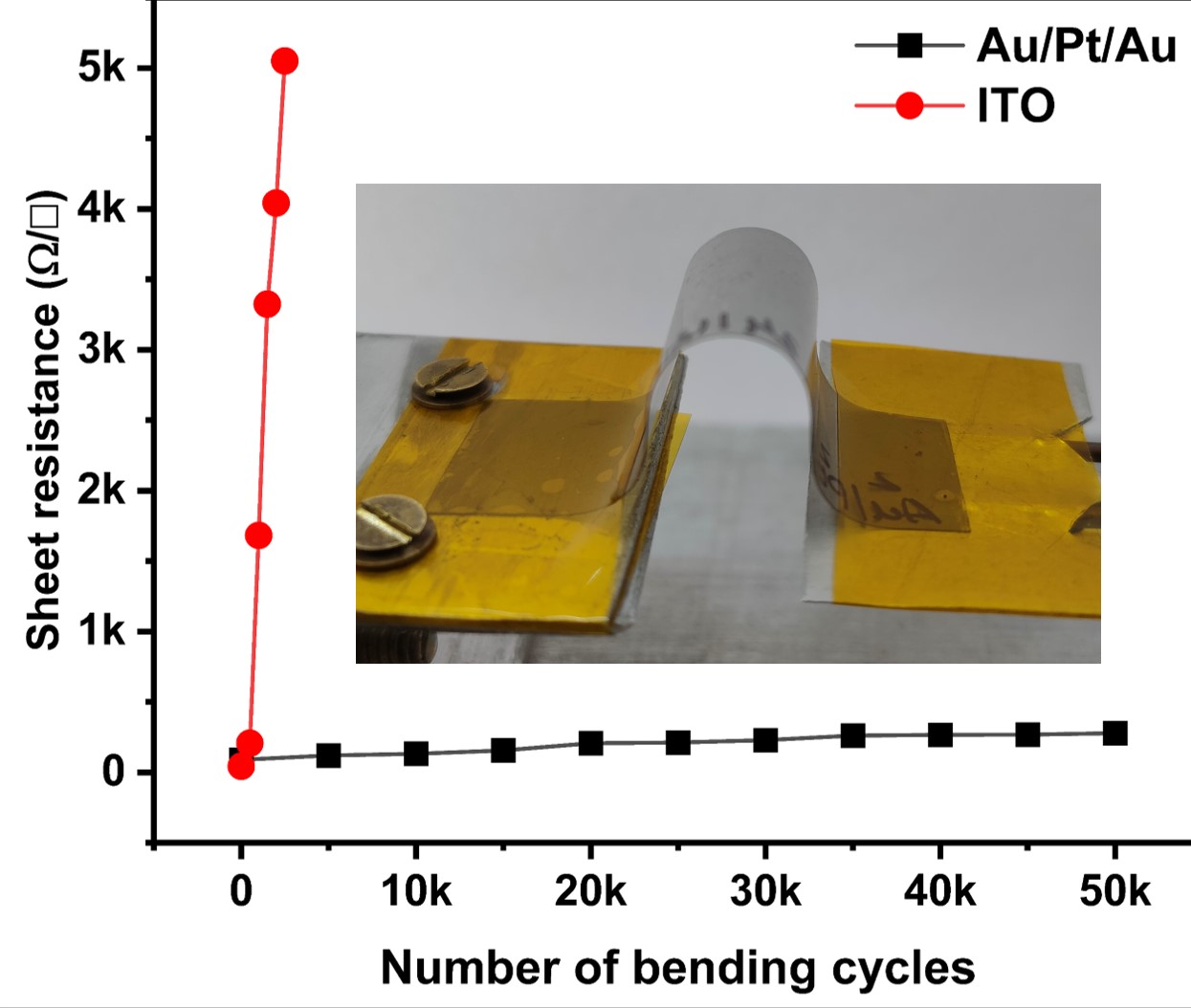

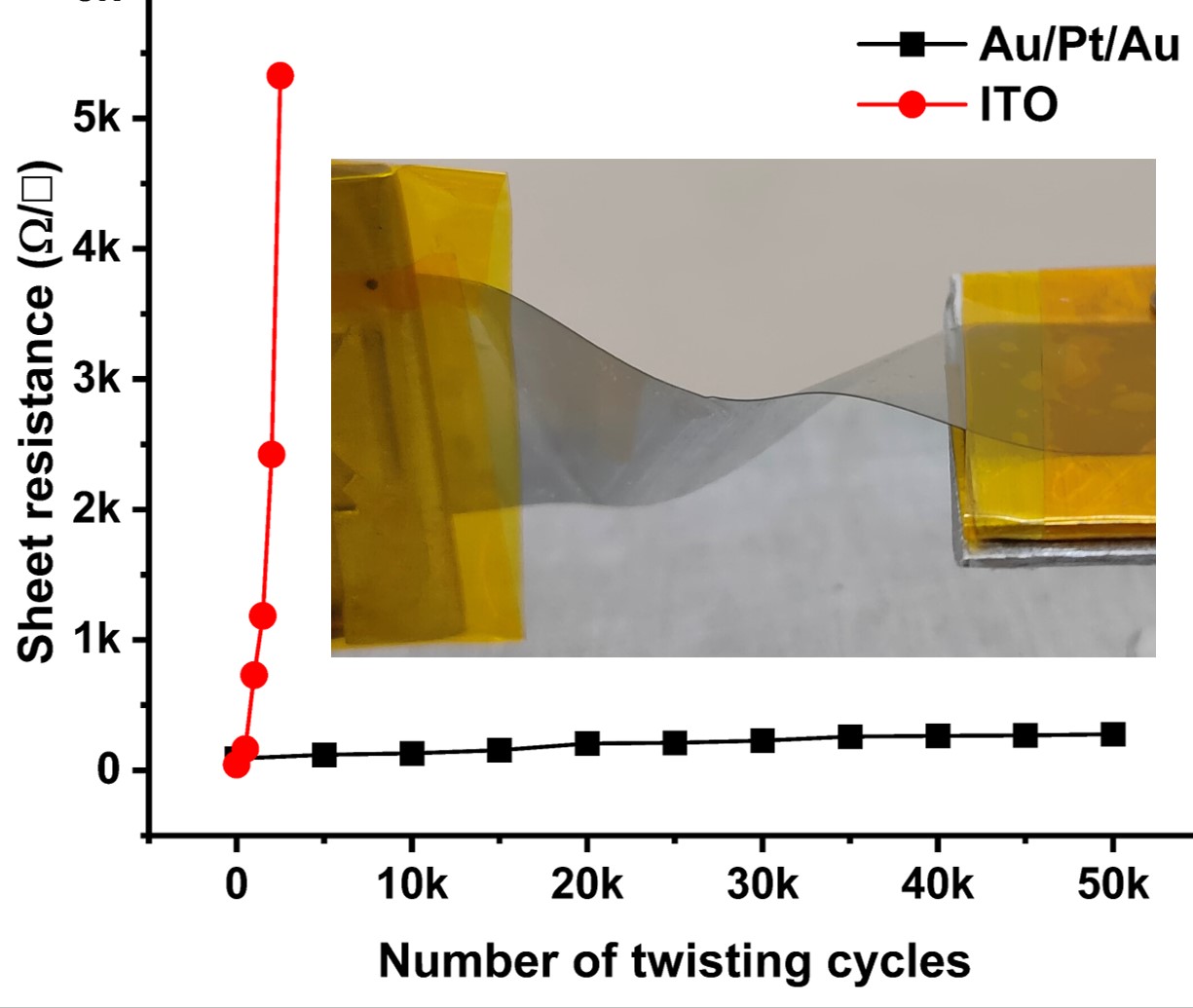

The sheet resistance of the flexible and transparent metallic conducting electrodes was better than that of indium-tin oxide with good optical transmittance: 55 percent transmittance in the UV–visible and near infrared regions. Moreover, the metallic tri-layer retained its optoelectronic properties even after 50,000 bending and twisting cycles!

To test its potential applications, the researchers tested the gold-platinum-gold film for use as an electrode. Small-scale physical changes in the film were converted into electricity: the film acted as a viable electrode with good conversion of mechanical energy and worked as a piezoelectric nanogenerator.

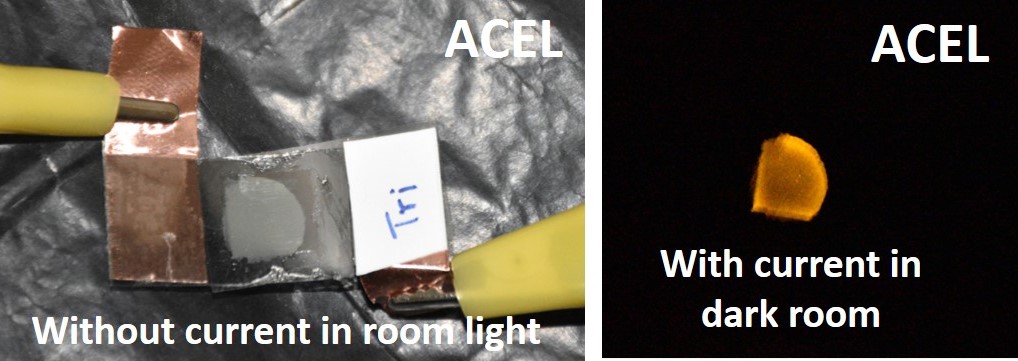

The metallic tri-layer electrodes also showed a capacity for long periods of operation when used in flexible electroluminescent devices running on alternating current.

The method of preparation of the metal multi-layers is commonly used for thin film deposition. So, the results of this research can be easily upscaled to suit the industrial fabrication of large, flexible, transparent and conducting electrodes.

Vacuum 206: 111487 (2022);

DOI: 10.1016/j.vacuum.2022.111487

Manish Kumar Tekam

IIT Indore

Leave a comment